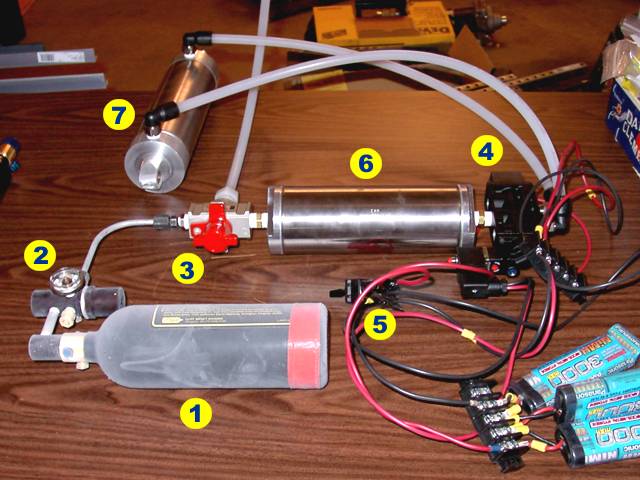

This page describes the current breadboard pneumatic setup for IceBerg. I have multiple

motives for describing it:

Translation: don't try this at home; if you do and screw up, don't sue me!

I don't have part numbers for the paintball components, because I ordered these from a local paintball pro-shop. They retailed the parts and put together custom tanks with anti-siphon tubes and on-off valves. I recommend this "in-person" approach, because the pro was able to describe the tank-filling process and suggest possible solutions to various engineering problems.

Note the coating of frost on the 20 oz. tank (1) after testing. At room temperature, liquid over gas CO2 will be between 800 and 900 psi. The regulator cuts that down to 150 psi. We get about 10 shots at full pressure, and 9 more shots at partial pressure.

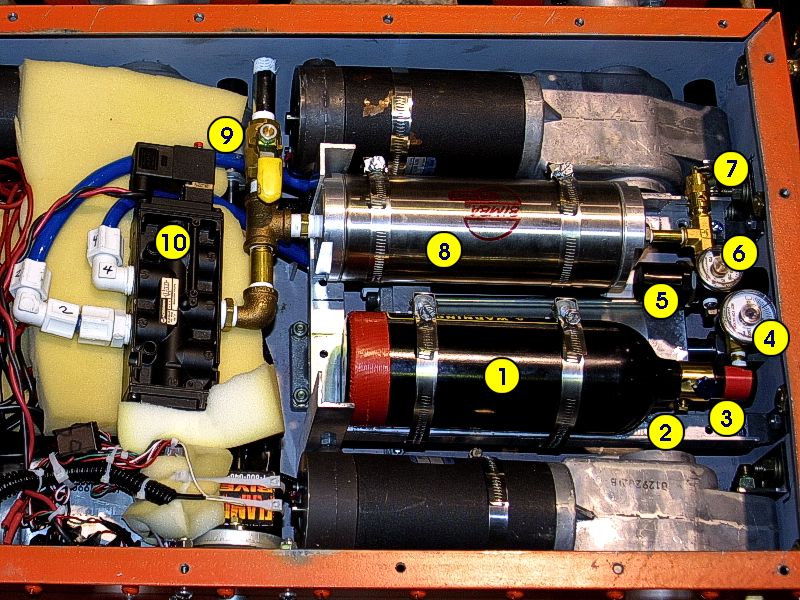

This larger photo shows the final setup after installation in the robot, and updated

for the BattleBots Tech Regs V1.0

as used for TI-2, Season 4.0. Note that the pneumatic valve was upgraded from a 3/8" port to a 1/2"

port valve, increasing the flow rate from 1.6 to 5.0 Cv, and making the weapon much faster. Also

note that the cylinder used in the final version was a smaller McMaster 2.5" x 4" stroke cylinder,

giving about 14 full pressure shots with the weapon (out and back counts as one activation), and

another 5-10 weaker shots.

This setup passed safety, once we demonstrated that the nylon tube fittings (McMaster part

5016K466. 5016K699, and 5016K144) were rated for 220 psi.

Also note that the stock McMaster foot bracket that is sold for the pneumatic cylinder is

made of cast aluminum, and is not strong enough for use in BattleBots, so find or make

something stronger for mounting your cylinder.

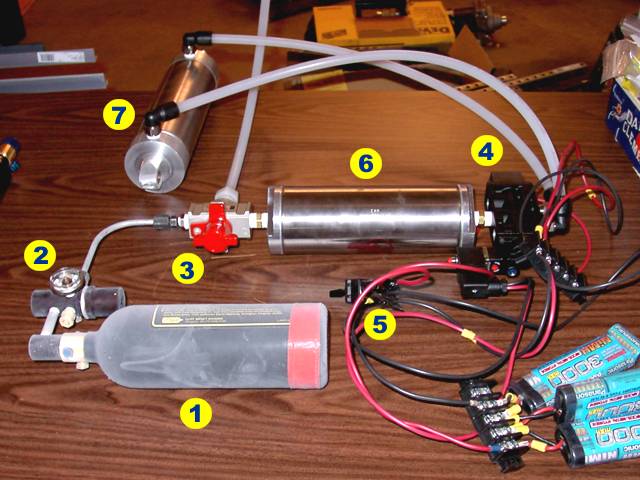

Regulator closeup

Updated for TI-2 Safety Rules